-

Call: +91 9657986606

Krishna Industries

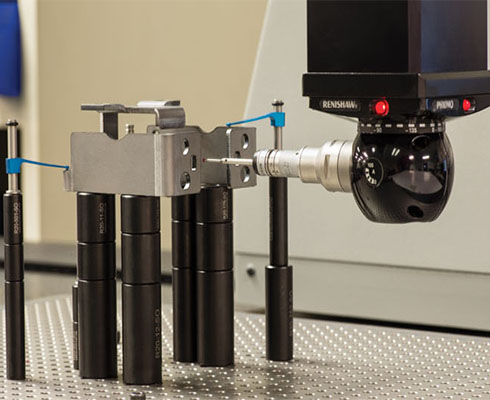

-: CMM Inspection :-

CMMs are industrial inspection tools that measure the dimensional accuracy of manufactured goods. This is a crucial step to monitoring production quality to ensure large-sized parts meet design specifications for use in critical applications.

Coordinate Measuring Machines are industrial tools that measure the dimensionality of objects. They use different mechanisms, such as scanners, touch-triggers, and vision probes, to measure objects along the X-, Y-, and Z-axis. The measurements can

then be compared to the initial design plans or specifications of the object to ensure the finished product is adequately identical to the original design. CMMs are typically constructed from granite and aluminum to ensure functionality and accuracy even in harsh temperatures and environments.